Pinch Flow Fractionation Micro Fluidic Device

This microfluidic device was designed for chemical engineering class CHBE 4200: Additive Manufacturing. Pinch Flow Fractionation (PFF) is a technique for continuously separating particles by size using laminar flow through a precisely designed microchannel geometry. Particles in suspension flow through a narrow “pinched” section where they are aligned along one wall by a co-flowing buffer. As the flow expands into a broad region, differences in particle size cause larger particles to occupy streamlines further from the wall, while smaller ones stay closer. This allows predictable, continuous separation according to flow profiles derived from the PFF scaling relationship. PFF is used in biomedical, environmental, and materials applications. Alternative methods such as Field Flow Fractionation (FFF) or Hydrodynamic Chromatography (HDC) require external fields (gravitational, centrifugal, or electrical), while PFF operates passively and continuously.

Design

Symmetric or asymmetric approach

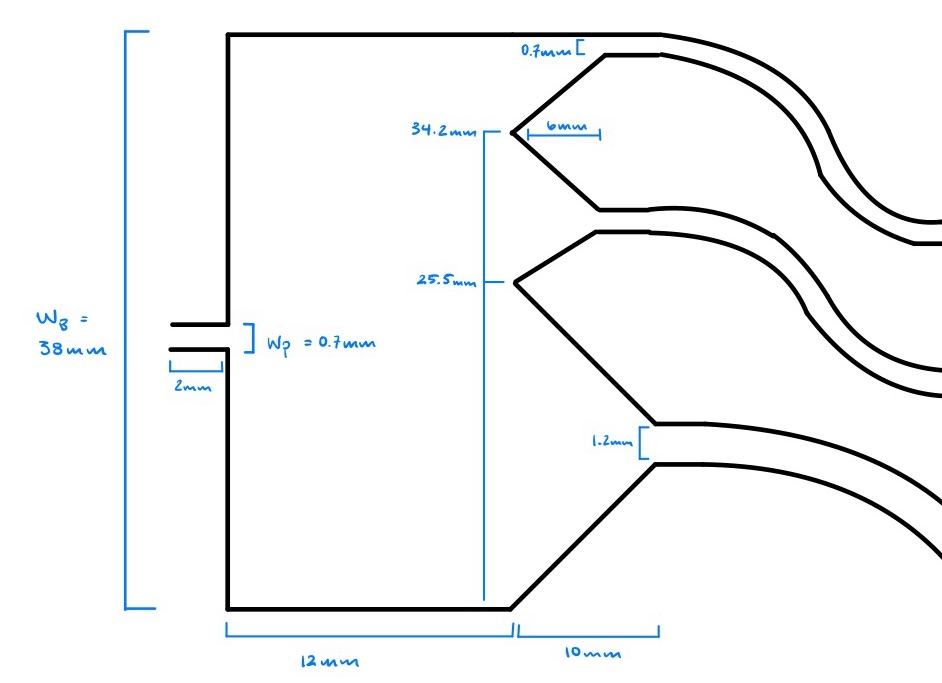

My design uses an asymmetric approach. In traditional PFF devices, the flow field and outlet resistances are uniform across the channel, which can lead to poor resolution and overlap between particle streams. The asymmetric configuration intentionally maintains one fixed pinch wall while allowing the opposite wall to expand asymmetrically into a wider region. This asymmetry, described by In this device the modelling and geometry draw from the Ashrafizadeh et al., 2025, enhances size-based separation by directing particle trajectories further apart under laminar flow, particularly improving resolution for smaller particles. In this design, the pinch section is 0.7 mm wide and expands asymmetrically to a broad section width of 38 mm providing a large field for particle spreading while preserving smooth, stable flow. I also designed my device with the intention of using rigid pipes instead of the typical flexible tubes used in hopes that the consistency of the rigid tubes would not create any unwanted pressures in the device.

Outlet boundary placement

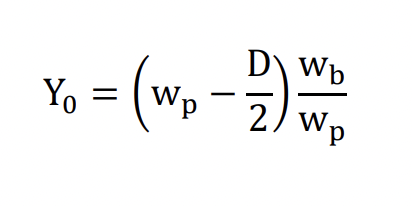

In this device the modelling and geometry draw from the Yamada et al. 2004 treatment of laminar band spacing: This equation from their work predicts the lateral position of each size band in the broadened region. Using a pinch width of 0.7 mm and broad section of 38 mm, the predicted band centers are 25.5 mm (large) and 34.2 mm (small) from the pinch wall, yielding outlet windows of 25.0, 7.7, and 3.3 mm. Each window narrows through a gentle taper to its neck (10 mm for the 1.2 mm buffer, 6mm for the two 0.7 mm particle lanes), followed by 2–3 mm of straight channel. Although the pre-neck widths differ, the particle outlets are length-matched downstream to equalize hydraulic resistance and maintain stable separation.

This equation from their work predicts the lateral position of each size band in the broadened region. Using a pinch width of 0.7 mm and broad section of 38 mm, the predicted band centers are 25.5 mm (large) and 34.2 mm (small) from the pinch wall, yielding outlet windows of 25.0, 7.7, and 3.3 mm. Each window narrows through a gentle taper to its neck (10 mm for the 1.2 mm buffer, 6mm for the two 0.7 mm particle lanes), followed by 2–3 mm of straight channel. Although the pre-neck widths differ, the particle outlets are length-matched downstream to equalize hydraulic resistance and maintain stable separation.

Flow Balancing

To maintain balanced flow between outlets, the design incorporates hydraulic-resistance matching consistent with the design principles outlined for asymmetrical PFF geometries. The buffer channel was designed as the low-resistance “drain,” remaining short and wide so that most of the sheath fluid exits through it. Both particle outlets were made narrower and longer, each with identical serpentine paths to equalize flow resistance and preserve the relative outlet flow fractions. This strategy ensures that the particle lanes carry only the desired fraction of the total flow without distorting the interface position within the broad section. Channel dimensions were confirmed by extruding each lane in CAD, measuring their volumes, and verifying that the two particle outlets had equal volumes (19.237 mm³), confirming identical hydraulic lengths.

Interactive CAD Model

Picutred Below:

Images 1-3 show resin printed mold, Images 4-5 show final device